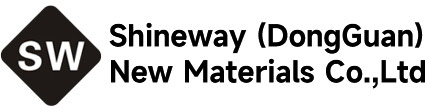

Conductive PE Foam¡¢ESD Footwear Materials¡¢Antistatic Insoles

- Product Description

Conductive PE Foam¡¢ESD Footwear Materials¡¢Antistatic Insoles

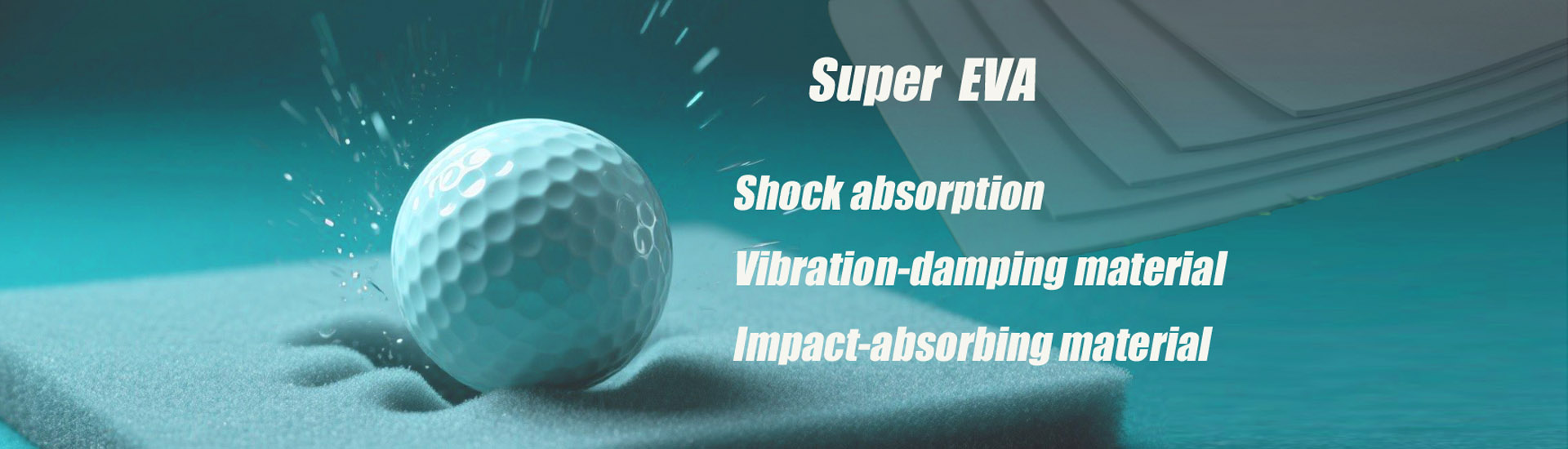

Conductive PE Foam is a type of foam material with conductive properties. Below is an introduction to its features and applications:

I. Features

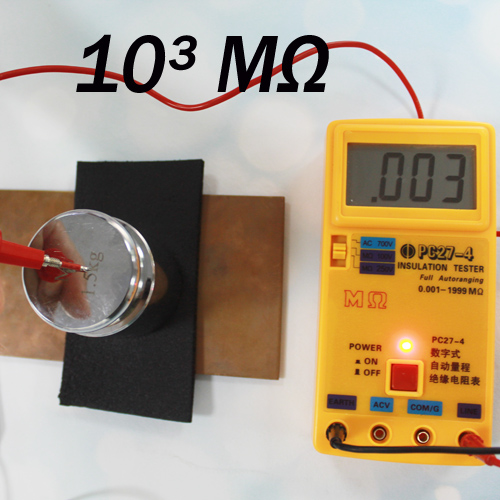

- Excellent Conductivity: It has a stable surface resistance, ranging from 10³ to 10⁵ M¦¸ (note: the original text "10^M¦¸" is corrected to the industry-common "10⁵ M¦¸" for accuracy). It can effectively conduct electric current or electromagnetic waves, and its conductivity is not affected by environmental humidity, remaining effective for a long time.

- Omni-Directional Conductivity: Some conductive PE Foam products undergo nickel plating after HOL-shaped holes are punched in the cushion material. This design ensures not only conductivity on the upper and lower surfaces but also connection between the plating on the inner walls of the holes and the plating on the upper/lower surfaces, achieving omni-directional conductivity.

- Superior Elasticity & Cushioning: PE Foam itself has excellent elasticity and is classified as a high-elasticity material. It boasts strong tensile strength and fast rebound performance, which enables it to effectively absorb impact and vibration, providing a certain level of cushioning and shock absorption to protect electronic devices from damage.

- Lightweight & Flexible: It is lightweight and easy to process and install. It can be die-cut into various shapes and sizes according to requirements, adapting to different application scenarios.

- Strong Corrosion Resistance & Weather Resistance: It is resistant to corrosion from organic solvents, acids, alkalis, and other chemical substances. It can adapt to various environmental conditions and maintain stable performance in different working environments.

- Eco-Friendly & Safe: Most products comply with environmental standards such as RoHS and REACH, being non-toxic and harmless. They do not cause environmental pollution during production, are easy to recycle after use, and do not cause severe air pollution when incinerated.

II. Applications

- Electronic Equipment Field: It is widely used in electronic products to reduce electromagnetic interference (EMI) and radiation. It protects key components such as circuit boards from electromagnetic wave interference while providing cushioning and shock absorption protection.

- Footwear & Protective Gear Field: Due to its eco-friendliness, safety, and low cost, it can replace some ESD products such as conductive insoles and protective gear, eliminating the need for stitching metal conductive wires. Its resistance to decomposition is particularly prominent, especially in humid environments.

III. Comprehensive Advantages & Disadvantages

- Comprehensive Advantages: Conductive PE products have low costs, resistance to hydrolysis and aging, and high environmental performance. They have applicable fields with suitable compatibility.

- Comprehensive Disadvantages: Their compression set and rebound resilience are significantly less stable than those of EVA. They are a secondary option in the footwear and protective gear fields.

We are a professional footbed factory supporting OEM/ODM services. Welcome to contact us for consultation.