PU Foam Antistatic Insoles, Conductive Insoles, ESD Footbeds

- Product Description

Product Introduction: PU Foam Antistatic Insoles, Conductive Insole, ESD Footbeds

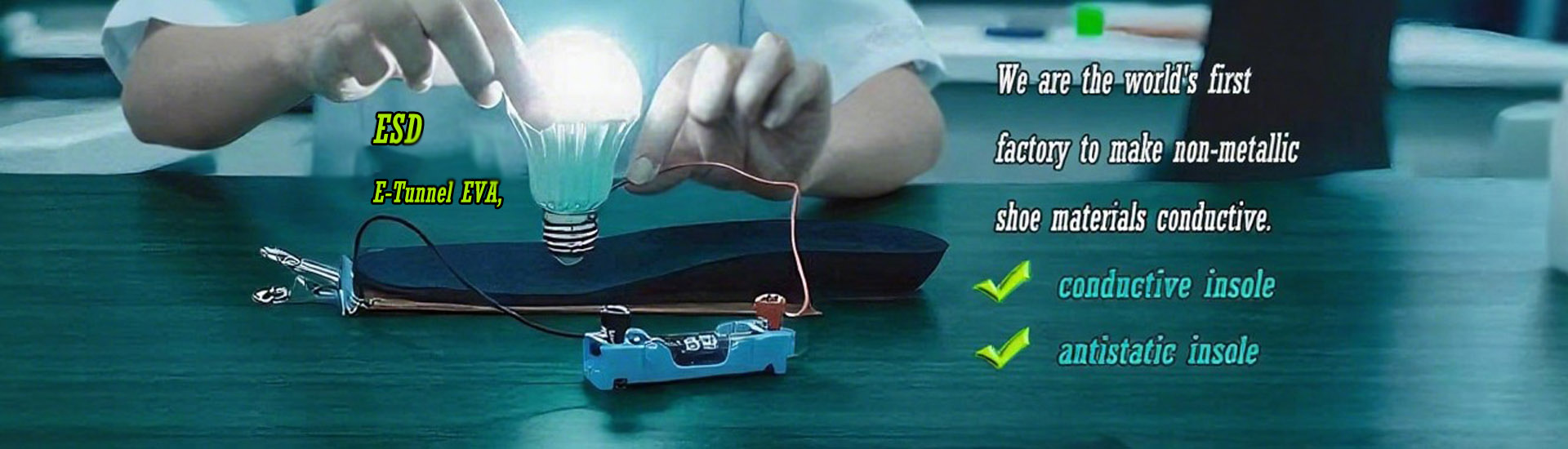

In industries sensitive to static electricity¡ªsuch as electronic manufacturing, semiconductor processing, and precision instrument assembly¡ªElectrostatic Discharge (ESD) from the human body can cause irreversible damage to products and even pose safety hazards. In addition to our EVA conductive product line, we have specially developed PU Foam Antistatic Insoles, Conductive Insoles, and ESD Footbeds for these scenarios. Combining scientific material composition and structural design, these products build the first line of foot-based ESD protection for users while ensuring the softness and breathability required for daily wear. Notably, this footbed contains no stitched conductive metal wires, eliminating risks associated with broken needles or wire breakage.

I. Core Materials: 3-Layer Structure for Both Protection and Comfort

Our ESD-protective insoles feature a "functional material layered composite" design, with each layer tailored to specific needs¡ªensuring uncompromised protection and sustained comfort:

-

Surface Layer:

Conductive Fabric

The top layer (in direct contact with the foot) uses high-conductivity textile fabric. It not only rapidly dissipates static electricity generated by the foot to prevent charge accumulation but also offers a soft, skin-friendly texture that reduces friction and irritation during prolonged wear. Additionally, the fabric¡¯s moisture-wicking property quickly absorbs foot sweat, keeping the sole dry. -

Middle Layer:

Conductive Recyclable PU Foam

The core cushioning layer is made of recyclable conductive PU foam. On one hand, its low-resistance property (resistance stably controlled at 10³¨C10⁵M¦¸) enables efficient conduction and dissipation of static electricity, meeting core ESD protection requirements. On the other hand, the high elasticity and low compression set of PU foam (resisting collapse after long-term use) effectively distributes plantar pressure, alleviating foot fatigue during standing or walking. -

Bottom Layer:

Ortholite Foam

The base is combined with industry-recognized Ortholite foam. Its signature open-cell structure creates efficient breathable channels, accelerating air circulation inside the shoe to further enhance the insole¡¯s moisture-wicking and breathability. Meanwhile, the cushioning performance of Ortholite foam complements the middle PU foam layer, making the overall support more ÌùºÏ to the plantar curve and balancing protection with walking comfort.

II. Core Advantages: 4 Key Features for Professional Scenarios

1. Stable Low Resistance for Reliable ESD Protection

Through optimized material formulations and synergistic effects of the 3-layer structure, the overall resistance of the footbed is strictly controlled within the range of 10³¨C10⁵M¦¸, fully complying with electronic industry ESD protection standards (e.g., ANSI/ESD S20.20). Whether standing while operating precision instruments or walking in static-sensitive workshops, it rapidly diverts human static electricity to the ground¡ªavoiding risks such as component damage from electrostatic breakdown, equipment interference, or dust explosions¡ªand safeguarding production safety.

2. Moisture-Wicking, Breathable, and High-Elastic for Uncompromised Comfort

Unlike traditional rigid ESD-protective insoles, our products prioritize wear comfort alongside protection:

- The dual-breathable design (conductive fabric + Ortholite foam) quickly expels moisture and heat from the shoe. Even during prolonged wear (8+ hours), it keeps the sole dry and minimizes stuffiness.

- The high elasticity of conductive PU foam deforms in response to plantar pressure, fitting key areas like the arch and heel. It disperses impact forces during walking or standing, relieving foot soreness¡ªideal for workshop workers, laboratory staff, and others who need to stand for long periods.

3. Eco-Friendly and Recyclable for Green Production

The conductive PU foam in the middle layer is recyclable. After the product reaches the end of its lifecycle, it can be processed and reused through professional recycling channels¡ªreducing the environmental burden of industrial waste and aligning with enterprises¡¯ needs for green production and sustainable development.

4. Conductive Performance Achieved via Pure Materials (No Stitched Conductive Wires)

Traditional conductive footbeds rely on stitched metal wires to create a conductive path between the top and bottom layers. This not only affects product aesthetics and causes significant foot discomfort during wear but also carries quality risks (e.g., broken needles or wire breakage) that may even lead to safety accidents. In contrast, our footbed achieves conductivity through pure materials¡ªcompletely eliminating the aforementioned risks while enhancing product appearance and improving wear comfort.

III. Application Scenarios: Precise Matching for Static-Sensitive Fields

- Electronic Manufacturing: Semiconductor chips, circuit boards, and electronic component assembly workshops (preventing static damage to precision products).

- Precision Instrument Industry: Laboratories and medical equipment operation environments (e.g., MRI, ultrasound devices) (avoiding static interference with equipment accuracy).

- Chemical/Flammable-Explosive Scenarios: Chemical material storage and spray-painting workshops (preventing safety accidents caused by static-induced sparks).

- ESD-Protected Areas: All workplaces marked as "static-sensitive zones" (serving as basic equipment for human ESD protection).

As a professional footbed factory, we offer OEM/ODM customization services to meet customer needs (e.g., adjusting insole thickness, size, resistance range, or printing brand logos). We welcome inquiries and cooperation from relevant enterprises to jointly create "safe + comfortable + eco-friendly" ESD-protective insole solutions!