Puncture-Resistant Midsole Fabric, Conductive Midsole Board, ESD Footwear Materials

- Product Description

Puncture-Resistant Midsole Fabric, Conductive Midsole Board, ESD Footwear Materials

1. Product Overview

In the footwear material industry, puncture-resistant midsoles are indispensable core protective components for safety shoes, military boots, and outdoor shoes. They can effectively resist the puncture risk from sharp objects on the ground (such as nails, iron filings, and glass shards), providing users with all-day foot protection.

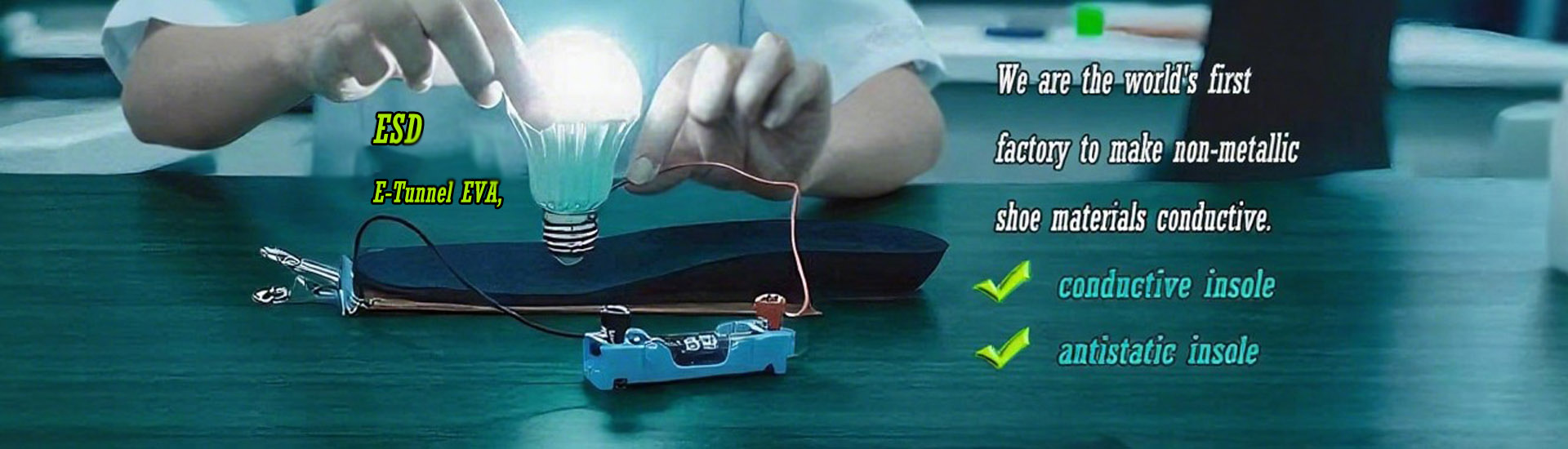

However, with the continuous innovation of products, the requirements for puncture-resistant midsoles have become increasingly higher. For example, on the basis of retaining the puncture-resistant function, they also need to achieve low electrical resistivity, minimize weight, and even enable secondary shaping. Our developed conductive puncture-resistant midsole has successfully solved this problem.

2. Materials & Structure

- High-Strength Fiber Fabric: Made of special yarn fibers, featuring high strength and high toughness.

- Multi-Layer Interlacing Technology: Through multi-layer interlacing, fibers form a tight protective network in multiple directions, effectively dispersing puncture force.

- Lightweight & Flexible: Compared with the first-generation puncture-resistant products, this midsole fabric is more flexible and lighter.

- Metal-Free Design: Will not trigger alarms when passing through security gates, complying with the parameter standards of the security inspection industry.

- Embedded Conductive Fibers: Different from the traditional impregnation process, this process enables permanent conductivity and wash resistance, without being affected by air humidity or the number of washes.

3. Protective Principle

The protective mechanism of the puncture-resistant midsole mainly relies on the tensile strength of high-strength fibers and the force dispersion effect of the interlaced structure:

- When a sharp object pierces, the force is dispersed to more fibers, reducing local stress.

- High-strength fibers themselves have extremely high breaking strength, which can resist penetration.

- The multi-layer structure forms a barrier layer, increasing the complexity of the overall puncture path, thereby significantly improving protective performance.

4. International Standards & Certifications

Our puncture-resistant midsole products comply with multiple international footwear safety standards, suitable for markets in Europe, North America, and Asia:

- EN ISO 20344 / 20345 (European Standards)

- Specify the test method for footwear puncture resistance. During the test, a force of 1100N (approximately 112kgf) is applied to the shoe sole, and the test nail must not pierce the midsole.

- Divided into two types of test requirements: non-metallic and steel.

- ASTM F2413 (American Standard)

- Has clear requirements for the puncture resistance of safety shoes. The test method is similar to European standards, with a focus on simulating actual working environments.

- CSA Z195 (Canadian Standard)

- Similar to ASTM, but imposes higher requirements on the performance of footwear in cold environments.

- China GB 21148 / GB 21146

- Stipulate requirements for the puncture protection and comfort of safety shoes, with test methods aligned with ISO standards.

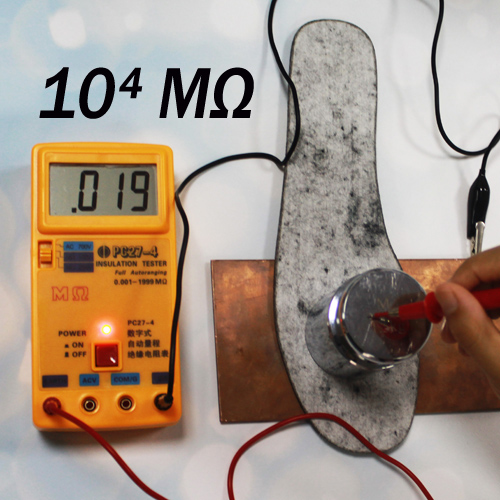

- The electrical resistivity is 10³¨C10⁵M¦¸, which far exceeds the existing international standards.

5. Application Fields

- Safety Shoes: Construction, manufacturing, logistics, mining.

- Military & Police Boots: Tactical operations, patrol missions.

- Outdoor Shoes: Wilderness exploration, hiking.

- Special Industries: Aviation security inspection, warehouse operations.

- Firefighting Boots: Explosive environments, sensitive flammable environments.

- Work Shoes: Static-free environments, oil depots, etc.

6. Our Advantages

- 100% Inspection Process: Each midsole undergoes strict testing to ensure stable performance.

- Lightweight Upgrade: Weight is reduced by approximately 40%¨C50% compared with traditional puncture-resistant midsoles.

- Breathable & Comfortable: Combined with a breathable textile structure, it enhances all-day wearing comfort.

- Customization Services: Can provide different thicknesses, flexibility levels, and shaping solutions according to customers¡¯ shoe style requirements.

We are an footbad factory supporting OEM/ODM services. Welcome to contact us for consultation.